If you’re wondering, “How does laser cutting service work?” you’ve come to the right place. Learn about the Focal spot, high-powered beam, and concentrated energy that lasers have. Read on to learn more about the advantages and disadvantages of laser cutting. Once you’ve read about the different benefits of laser cutting, you can decide on the best laser cutter for your needs. And, as always, be sure to follow our helpful tips to get the best results.

Focal spot for laser cutting

In laser cutting, a concave mirror or lens is used to focus a beam of light. This beam must be focused on a small spot with sufficient power density to cut the material. The focal length is the distance over which the focused area does not increase more than 50%. The focal length of a CO2 laser is typically 5″ to 7.5″.

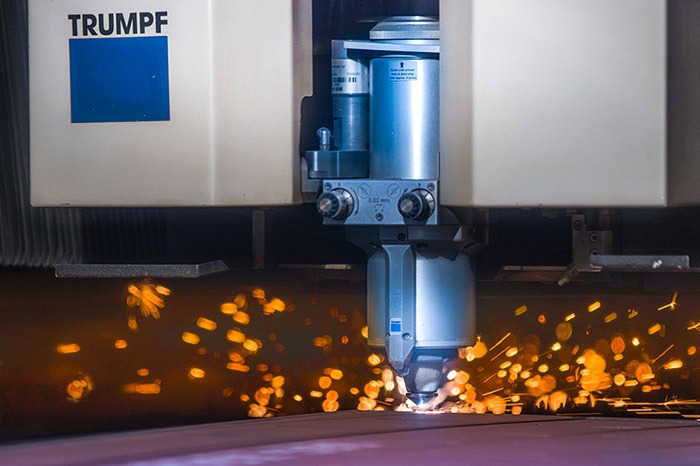

High-powered laser beam

Optical equipment is used to focus the beam, which must be circular and even. A special lens or curved mirror helps focus the beam. The laser beam is centered within the nozzle. Like how a magnifying glass concentrates the sunlight on a leaf, the laser beam must be round and consistent. Its intensity should be higher than 6 KWatts. A beam of this intensity is capable of creating extreme heat density.

Concentrated energy

The power of laser cutting is dependent on the amount of laser energy it uses. The more energy the laser uses, the wider the cut and the more material it removes from the edges. On the other hand, less energy can yield a shallower cut and a straighter edge. The amount of material removed depends on the thickness and hardness of the material. Denser materials require more energy and may produce smoke and charred edges.

Reduced post-processing requirements

Laser cutting can dramatically reduce the post-processing requirements of metal fabrication projects. Compared to traditional methods such as machining by hand, laser cutting can produce pieces with higher accuracy and reduced post-processing requirements. Unlike hand cutting, laser cutting is safer and faster. However, some materials may not respond well to laser cutting, where CNC table speed and nozzle diameter come into play. To ensure the optimal cutting process for your specific project, we have put together a list of benefits of laser-cutting metal.